Boiler Service Checklist Validator

This tool helps you verify if your boiler service included all mandatory tasks. Check the boxes for each item you were told was done during your service.

Mandatory Service Items

Optional Service Items

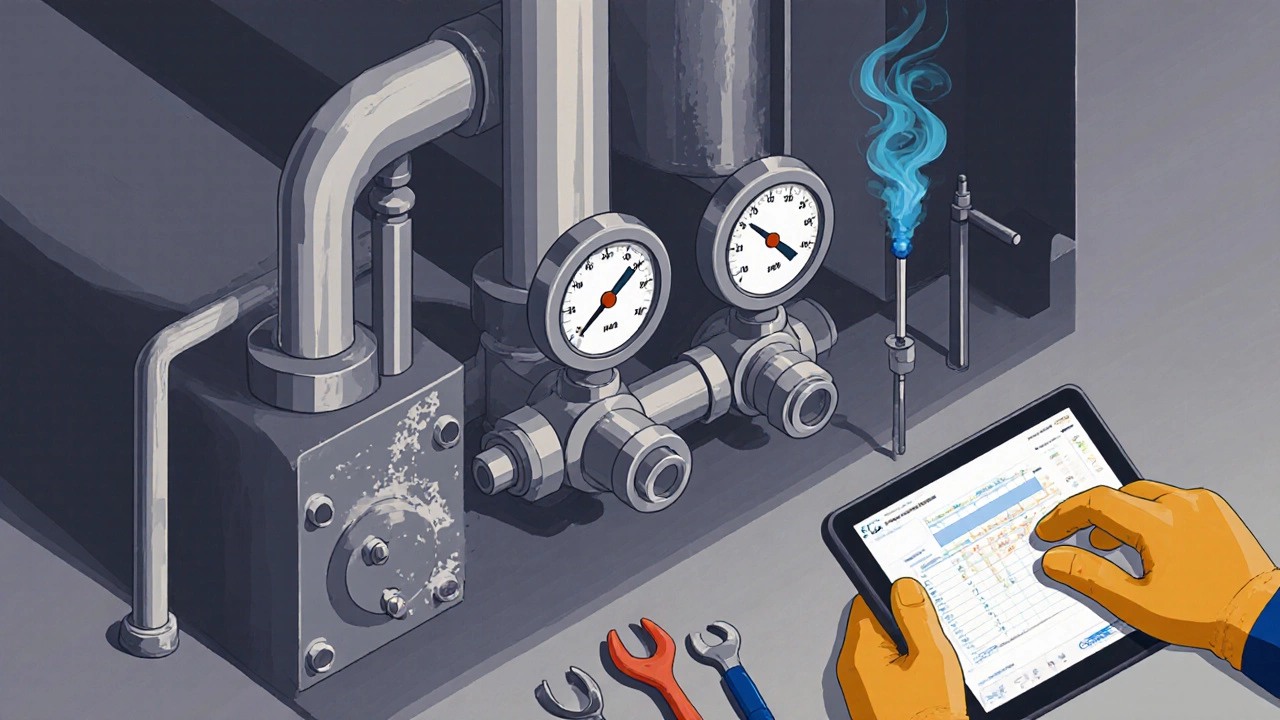

When winter rolls around, a chilly home is the last thing you want. That’s why a thorough boiler service isn’t just a good idea-it’s a safety net for your family and your wallet. In this guide we’ll walk through every step a qualified engineer takes, why each task matters, and how you can tell if you’re getting the right service.

What a Professional Boiler Service Covers

During an annual service a certified gas engineer follows a detailed checklist. The core items are:

- Visual inspection of the boiler and surrounding area

- Testing and calibrating the pressure gauge

- Checking the safety valve for proper release pressure

- Examining the heat exchanger for corrosion or blockages

- Running a combustion analysis

- Inspecting the flue and condensate trap

- Verifying thermostat and control functions

- Cleaning the burner and fan components

- Assessing the expansion tank and water level

Each of these steps is designed to keep your heating system efficient, reliable, and safe.

Key Components Explained

Boiler is a closed vessel that heats water for central heating and domestic hot‑water supply. A well‑maintained boiler converts fuel into heat while minimizing waste and emissions.

Pressure gauge shows the water pressure inside the system, usually measured in bar. Ideal pressure ranges between 1 and 1.5 bar when the system is cold. If the gauge reads outside this range, the engineer will adjust the filling loop or investigate leaks.

Safety valve is a fail‑safe device that opens if pressure exceeds a set limit, preventing explosions. The technician will lift the valve manually to confirm it releases at the correct pressure.

Heat exchanger transfers heat from the burning fuel to the water circuit. Over time, limescale or corrosion can reduce efficiency, so the engineer checks for deposits and signs of wear.

Combustion analyzer measures carbon monoxide (CO), oxygen (O₂), and carbon dioxide (CO₂) levels in the flue gases. Proper combustion should produce low CO (below 30 ppm) and a balanced O₂ reading (around 5‑10%). This test ensures the furnace is burning cleanly and safely.

Flue is the pipe that vents exhaust gases outside. A visual inspection looks for rust, blockages, or signs of condensation that could corrode the pipe. In condensate‑type boilers, the condensate trap is also checked for clogs.

Why Each Check Is Crucial

Ignoring any of these items can lead to costly breakdowns or dangerous situations. For example, a stuck safety valve might allow pressure to climb, risking a burst pipe or, in extreme cases, an explosion. A dirty heat exchanger reduces thermal efficiency by up to 15 %, raising fuel bills.

Carbon monoxide is odorless and lethal; a poor combustion reading means the boiler is leaking CO into your home, which is why modern regulations require annual testing.

How Often Should You Schedule a Service?

Most manufacturers and insurance policies recommend an annual service, ideally before the heating season starts. If you notice frequent pilot‑light issues, strange noises, or rising energy bills, an extra check mid‑year can catch problems early.

Older cast‑iron boilers might benefit from a bi‑annual service, while newer condensing models typically stick to the once‑a‑year rule.

Choosing the Right Engineer

Look for a Gas Safe registered engineer (UK) or a licensed plumber with boiler‑service credentials in New Zealand. Ask about their experience with your boiler brand-some specialists focus on Baxi, Vaillant, or Worcester‑Yorkshire models.

Certified engineers carry liability insurance and follow the latest safety standards. Don’t hesitate to request a copy of their certificate before they start work.

DIY vs. Professional: What You Can Do Yourself

There are a few simple tasks homeowners can safely perform between professional visits:

- Check the pressure gauge and top up the system if it falls below 1 bar.

- Bleed radiators to remove trapped air, which improves heat distribution.

- Ensure the area around the boiler stays clear of clutter for better ventilation.

- Test the thermostat by raising the temperature and confirming the boiler fires.

Anything involving gas, internal components, or combustion testing should be left to a qualified professional.

Cost Expectations and What Influences Price

In Wellington, a standard annual boiler service runs between NZ$180 and NZ$250, depending on boiler type and any required parts. Factors that can raise the price include:

- Replacement of a faulty safety valve

- Flue cleaning or repair

- Descaling of a heavily scaled heat exchanger

- Emergency call‑out fees outside regular business hours

Ask for a written estimate before work starts; reputable firms will itemize each charge.

Boiler Service Checklist - Mandatory vs. Optional Tasks

| Task | Mandatory? | Typical Frequency |

|---|---|---|

| Visual inspection of casing and pipework | Yes | Every service |

| Pressure gauge test and adjustment | Yes | Every service |

| Safety valve release test | Yes | Every service |

| Combustion analysis | Yes | Every service |

| Heat exchanger inspection | Yes | Every service |

| Flue and condensate trap clean | Yes | Every service |

| Thermostat calibration | No | As needed |

| Fan and pump lubrication | No | Every 2‑3 years |

| Expansion tank pressure check | No | Every 2 years |

Focusing on the mandatory items keeps your system compliant with warranty terms and insurance requirements.

Common Myths About Boiler Service

Myth 1: “If the boiler is working, I don’t need a service.” Even a perfectly heating boiler can develop hidden carbon‑monoxide leaks or pressure‑related wear.

Myth 2: “I can clean the heat exchanger myself.” The heat exchanger sits inside a sealed pressure vessel; opening it without proper tools voids safety certifications.

Myth 3: “A cheap service is just as good as an expensive one.” Lower‑priced providers may skip the combustion test or use unqualified staff, putting you at risk.

Next Steps - Getting Your Boiler Ready for Service

1. Clear a 1‑meter radius around the boiler to allow easy access.

2. Locate the user manual; many manufacturers include a service log sheet you can fill in.

3. Call at least two Gas Safe‑registered engineers for quotes. Mention your boiler model and any recent symptoms.

4. Schedule the appointment early in the season-ideally September in New Zealand-to avoid a rush. When the engineer arrives, watch the process briefly. This helps you understand what’s being done and builds confidence for future services.

How long does a typical boiler service take?

A standard annual service usually takes between 45 minutes and 1.5 hours, depending on the boiler’s age and condition.

Can I get a discount if I sign up for a service contract?

Many companies offer a reduced rate for multi‑year contracts or bundled maintenance packages. Ask the engineer about loyalty discounts.

What are the warning signs that my boiler needs an urgent service?

Strange noises, a sudden drop in pressure, yellow or flickering flames, persistent leaks, or the smell of gas are all red flags that require immediate professional attention.

Is a boiler service mandatory for insurance?

Most home‑insurance policies stipulate an up‑to‑date service record. Failing to service regularly may lead to reduced coverage or claim denial.

Do I need to be home during the service?

It’s best to be present, especially for the combustion test, so you can ask questions. However, most engineers can complete the work unattended if you grant permission.