If your tumble dryer runs but the drum won’t spin, you’re not alone. This is one of the most common complaints we see in appliance repair shops. The dryer heats up, the timer counts down, and you hear the motor hum-but the clothes stay bunched up, wet, and tangled. It’s frustrating, especially when you need clean laundry fast. The good news? Most of the time, this isn’t a sign that your dryer is dead. It’s usually one simple part that’s worn out or misaligned.

Check the Drive Belt First

The drive belt is the most likely culprit. It’s a rubber loop that wraps around the drum and connects to the motor pulley. Over time, it stretches, cracks, or snaps. A broken belt means the motor spins, but the drum doesn’t move. You’ll hear the motor running, but there’s no drum rotation.

To check it, unplug the dryer and remove the front panel. Look for the belt around the drum. If it’s broken, frayed, or completely missing, that’s your problem. Even if it looks intact, try turning the drum by hand. If it spins too easily with no resistance, the belt has lost tension or slipped off the pulley. Most dryers use a single belt, and replacements cost under $25. Replacing it takes about 30 minutes with basic tools.

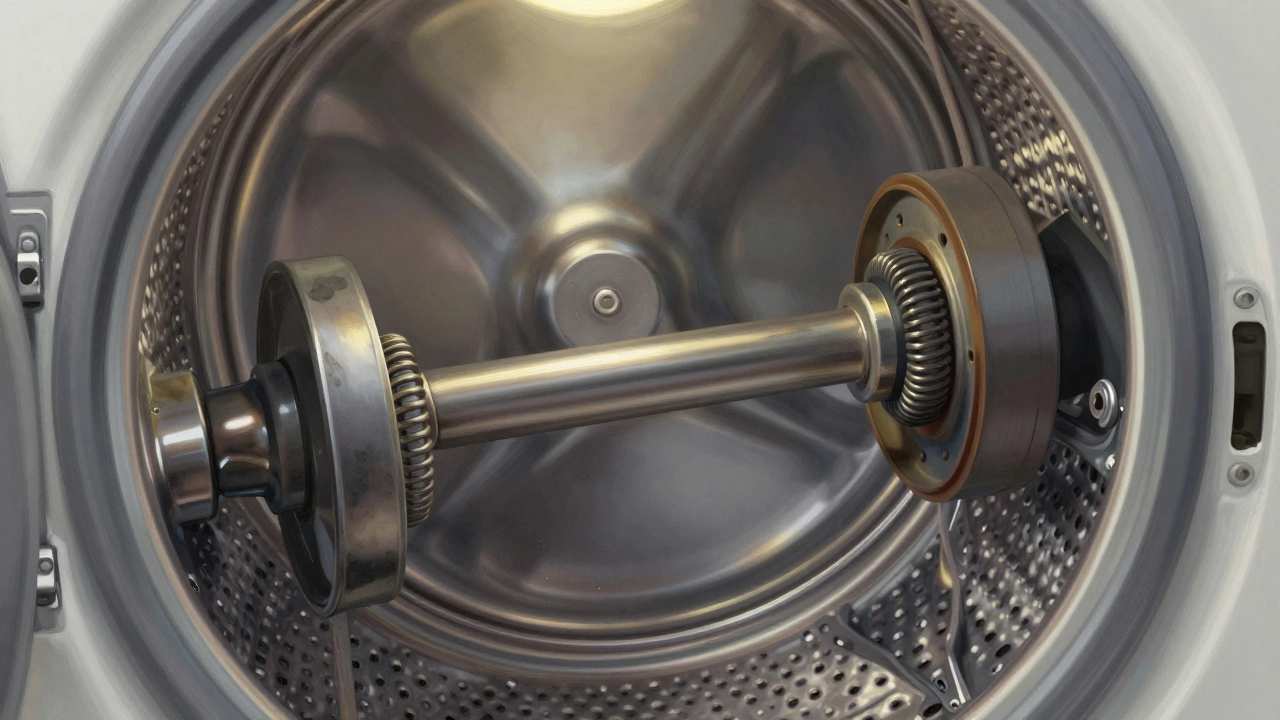

Inspect the Drum Rollers and Bearings

Even if the belt is fine, the drum might not spin because the rollers or bearings that support it have worn out. These small plastic or metal wheels sit under the drum and let it rotate smoothly. When they go bad, they grind, squeak, or lock up. A seized roller adds too much friction for the motor to overcome.

Look for flat spots, cracks, or rough surfaces on the rollers. If one is stuck or doesn’t turn freely when you spin it by hand, replace the whole set. Most dryers have two or four rollers. Replacing them as a group prevents uneven wear. You’ll also want to check the drum shaft for signs of rust or bending-this can cause the drum to wobble and bind.

Test the Motor and Capacitor

The motor itself could be failing, but it’s less common than belt or roller issues. If the motor hums but doesn’t turn, the problem might be the start capacitor. This small cylindrical component helps the motor get up to speed. A bad capacitor lets the motor buzz but prevents full rotation.

To test it, unplug the dryer and locate the capacitor near the motor. It’s usually a black or silver tube with two wires. Use a multimeter set to capacitance mode. If the reading is way below the value printed on the capacitor (usually 10-20 microfarads), it needs replacing. A new capacitor costs $10-$15 and installs in minutes. If the motor doesn’t hum at all, it could be dead-but that’s rare unless the dryer is over 12 years old.

Look for a Faulty Idler Pulley

The idler pulley keeps tension on the drive belt. It’s a small wheel pressed against the belt by a spring. When it wears out, the belt slips or falls off. You’ll hear a high-pitched squeal or a rhythmic thumping as the drum tries to turn. The pulley might also be cracked or have a flat spot from constant pressure.

Remove the belt and spin the idler pulley by hand. If it wobbles, makes noise, or doesn’t spin smoothly, replace it. Most idler pulleys come as a kit with the spring and mounting bracket. This is a cheap fix-under $20-and often overlooked because people focus only on the belt.

Check for Overloading or Obstructions

Before you start replacing parts, make sure the dryer isn’t just overloaded. A drum packed with heavy wet towels can overwhelm a weak motor or a slightly worn belt. Try running a small load-just a couple of shirts-and see if it spins normally.

Also, check inside the drum for foreign objects. A bra wire, coin, or sock stuck between the drum and the housing can jam the rotation. Turn the drum by hand slowly. If you feel resistance in one spot, something’s caught. Remove it before assuming a mechanical failure.

When to Call a Professional

If you’ve checked the belt, rollers, idler pulley, and capacitor-and the drum still won’t spin-it’s time to consider deeper issues. The motor might be burned out, the control board could be faulty, or the drum bearings might be fused to the shaft. These are harder to diagnose without specialized tools.

Also, if your dryer is more than 10-12 years old, it might be more cost-effective to replace it. New models are 30-40% more energy efficient and come with better moisture sensors and quieter motors. If the repair cost is more than half the price of a new dryer, it’s usually not worth fixing.

Preventing Future Problems

Regular maintenance keeps your dryer spinning smoothly. Clean the lint filter after every load. Every six months, vacuum the lint trap housing and the vent duct. A clogged vent forces the motor to work harder, which wears out belts and bearings faster.

Avoid overloading the drum. Leave at least a hand’s width of space between the clothes and the drum wall. Heavy items like blankets and towels should be dried in smaller batches. And never ignore strange noises-squeaks, thumps, or grinding are early warnings.

Most dryers last 10-15 years with basic care. If yours is younger than that and you’ve caught the problem early, you’re likely looking at a $30-$70 repair-not a new appliance.

Why does my dryer run but the drum doesn’t spin?

The most common reason is a broken or loose drive belt. Other causes include worn drum rollers, a faulty idler pulley, a failed start capacitor, or an obstruction jamming the drum. The motor may still run, but without proper belt tension or support, the drum won’t turn.

Can a clogged vent cause the dryer drum to stop spinning?

No, a clogged vent won’t stop the drum from spinning, but it can make the motor work harder and overheat. This can lead to premature wear on the belt, rollers, or motor. While the vent doesn’t directly affect rotation, it’s still critical to clean it regularly to prevent fire hazards and extend your dryer’s life.

How do I know if the dryer belt is broken?

If the drum spins very easily when you turn it by hand with no resistance, the belt is likely broken or slipped off. You might also hear the motor running but no drum movement. Visually inspecting the belt inside the dryer-after unplugging and removing the front panel-will confirm if it’s snapped, cracked, or missing.

Is it safe to keep using a dryer that doesn’t spin properly?

No. Running a dryer with a broken belt or seized drum puts extra strain on the motor and can cause it to overheat or burn out. It also increases fire risk because clothes stay damp and heat builds up in one spot. Stop using it immediately and diagnose the issue.

Can I replace the drive belt myself?

Yes, most homeowners can replace a drive belt with basic tools: a screwdriver, pliers, and maybe a socket wrench. It takes 20-40 minutes. Watch a model-specific video on YouTube first. Make sure you get the correct belt for your make and model-using the wrong size can cause more damage. Parts are inexpensive and widely available online.

What’s the average cost to fix a dryer that won’t spin?

DIY repairs for belts, rollers, or capacitors cost $10-$50 in parts. Professional repairs range from $100 to $250, depending on labor and part availability. If the motor or control board is faulty, expect $200-$400. For dryers over 10 years old, replacement is often cheaper than repair.