Washing Machine Failure Diagnostic

Troubleshooting Guide

Select the symptoms you're experiencing to identify potential problems with your washing machine.

Possible Failure

Washing machines are built to last, but they don’t last forever. If your machine is making strange noises, leaking water, or just won’t spin, it’s not always a power issue or a faulty setting. More often than not, it’s one of a few key parts wearing out. Knowing which parts fail most often can save you time, money, and a lot of frustration.

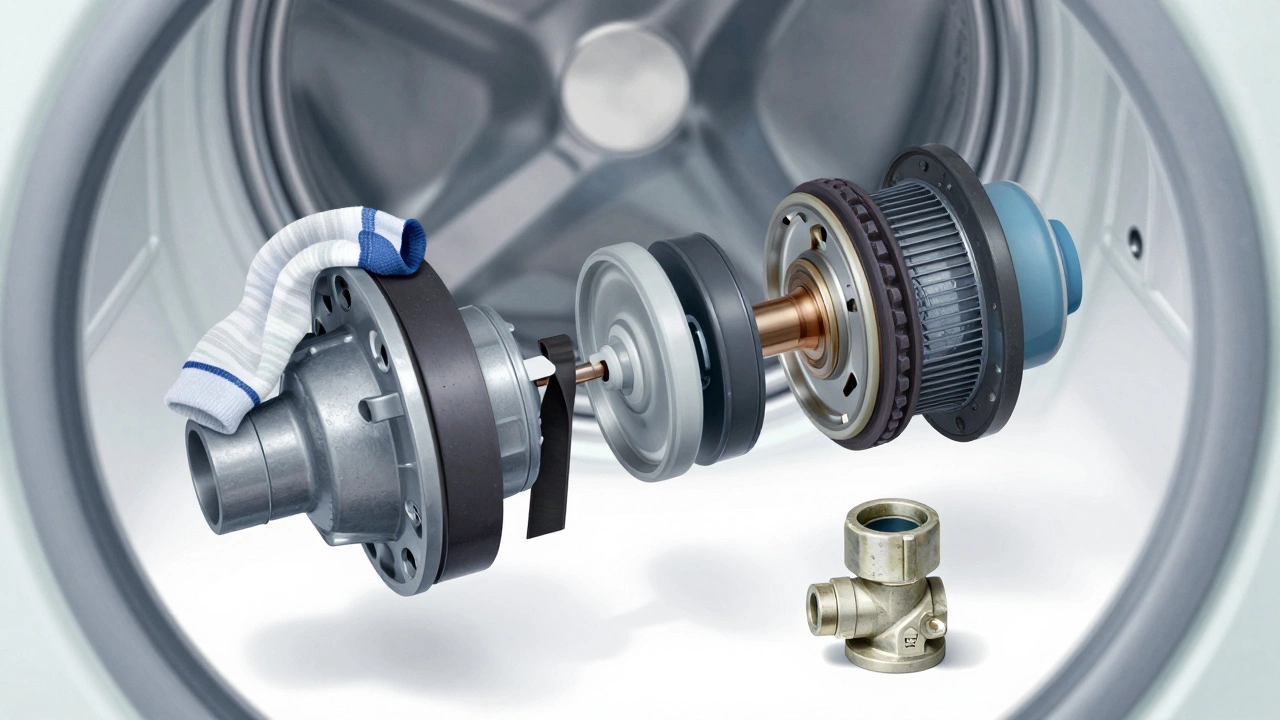

Drum Bearings

One of the most common reasons a washing machine starts making loud grinding or rumbling noises is worn drum bearings. These bearings support the inner drum as it spins at high speeds-sometimes over 1,000 RPM. Over time, water seeps past the rubber seal around the drum, rusting the metal bearings inside. Once they start to fail, the drum wobbles, the noise gets louder, and eventually, the machine won’t spin at all.

You can test this by opening the door and trying to move the drum up and down. If there’s more than a few millimeters of play, the bearings are gone. Replacing them isn’t cheap-often $200-$400 depending on the model-but it’s usually cheaper than buying a new machine. If you ignore it, the damaged bearings can ruin the drum shaft or even crack the outer tub, turning a fixable problem into a total loss.

Door Seal (Bellow)

The rubber door seal, also called the bellow, keeps water inside the drum during the wash cycle. It’s made of flexible rubber and sits between the door and the drum. Over time, it collects soap scum, mildew, and lint. If it’s cracked, torn, or stiff, it won’t seal properly. That means water leaks onto the floor, especially during the spin cycle.

It’s not hard to spot. Look for black mold streaks, small holes, or pieces of the rubber peeling away. A damaged seal can also cause clothes to get trapped and torn during the cycle. Replacing it is a DIY job for most front-loaders, but you need the exact model-specific part. Generic seals won’t fit right and will leak again within weeks.

Drain Pump

If your washer fills with water but won’t drain, the drain pump is the first suspect. It’s a small electric motor with an impeller that pushes water out through the drain hose. Over time, lint, coins, buttons, and even socks get sucked into the pump and jam the impeller. Sometimes the motor burns out from overuse or age.

You can check it by unplugging the machine, tilting it slightly, and looking under the front panel. Most models have a small access panel to clean out the pump filter. If you find a sock or a pile of lint, clean it out. If the pump still doesn’t run after cleaning, it’s likely dead. Replacement pumps cost between $50 and $120. If you’re not comfortable working with electrical components, call a technician.

Water Inlet Valve

This valve controls how much water flows into the machine during the fill cycle. It has two solenoids-one for hot water, one for cold. If one of them fails, you might get only cold water even when you select warm. If both fail, the machine won’t fill at all.

Signs of a bad inlet valve include long fill times, no water entering the drum, or water dripping after the cycle ends. You can test it by listening for a click when the machine starts filling. If there’s no click, the valve may not be receiving power-or it’s clogged with mineral deposits from hard water. Cleaning the filter screens inside the valve can help, but if the solenoid is burnt out, you need a new valve. They cost $40-$80 and are usually easy to swap out.

Drive Belt

The drive belt connects the motor to the drum. In top-loaders, it’s usually a flat rubber belt. In front-loaders, it’s a toothed belt that grips a pulley. If the belt is cracked, stretched, or broken, the drum won’t spin-even if the motor is running. You might hear a squealing noise or a humming sound without movement.

Replacing a drive belt is one of the simpler repairs. You’ll need to remove the back panel, loosen the motor mount, and slip the new belt on. It’s not expensive-$15-$40-but it requires some patience. If the belt keeps breaking, the problem might be misaligned pulleys or worn drum bearings putting extra strain on it.

Motor Coupler (Top-Loaders Only)

Many older top-loading washers use a plastic motor coupler to connect the motor shaft to the transmission. It’s a small, three-piece part made of plastic and rubber. Over time, the plastic wears down or cracks, especially if the machine is overloaded. When it fails, the motor runs, but the drum doesn’t spin or agitate.

This is a classic failure in machines over 8-10 years old. You can check it by removing the control panel and looking at the coupler. If the plastic centers are split or the rubber is mushy, it’s done. Replacement kits cost under $20 and are a common fix for brands like Whirlpool and GE. Newer top-loaders use direct-drive motors, so this part doesn’t apply to them.

Control Board

Modern washing machines rely on electronic control boards to manage cycles, water levels, and motor speed. If your machine displays error codes, doesn’t respond to buttons, or randomly stops mid-cycle, the control board could be the issue. But don’t jump to this conclusion-it’s often the last thing to check.

Control boards fail due to power surges, moisture, or overheating. They’re expensive-$150-$300-and not always worth replacing unless the machine is less than five years old. Before replacing it, make sure the problem isn’t a faulty door lock, sensor, or water level switch. Many times, a simple reset or cleaning the connections fixes the issue.

Spin Clutch (Top-Loaders)

Older top-loaders use a mechanical clutch to engage the spin cycle. When you select spin, the clutch locks the transmission to the drum. If the clutch is worn, the drum spins slowly or not at all, even though the motor is running. You might also notice a burning smell or the machine takes forever to drain.

Clutches wear out from heavy loads and frequent use. Replacing one is labor-intensive-it requires removing the transmission-but it’s cheaper than buying a new washer. Clutch kits run $60-$100. If you’re not experienced with appliance mechanics, this is a job for a professional.

What to Do When Something Breaks

Don’t panic. Most washing machine failures are fixable. Start by checking the simple stuff: Is the machine level? Is the drain hose kinked? Did you overload it? Sometimes, a loose power cord or a tripped circuit breaker looks like a broken part.

When you suspect a part failure, look up your model number online. Most manufacturers have repair manuals and parts diagrams. YouTube has step-by-step videos for nearly every model. If you’re unsure, take a photo of the problem and ask a repair technician. Many offer free diagnostics.

Repairing your washer is almost always cheaper than replacing it-unless the machine is over 10 years old and the repair costs more than half the price of a new one. Even then, if the machine runs well otherwise, fixing it makes sense. The average lifespan of a washing machine is 11-13 years. If yours is still going strong, it’s worth keeping.

Preventing Future Failures

Regular maintenance keeps your machine running longer. Here’s what works:

- Wipe the door seal dry after every use to prevent mold.

- Run a hot wash with vinegar or a washing machine cleaner every month to clear out buildup.

- Don’t overload the drum-it strains the bearings, belt, and motor.

- Use HE detergent in front-loaders. Regular detergent creates too many suds and damages the pump.

- Check the drain pump filter every 3-6 months. Remove lint and debris.

- Keep the machine level. Uneven floors cause extra vibration and wear on bearings.

These small habits can add years to your machine’s life-and save you hundreds in repairs.